Carrier Series 160 Manual

Installation, Start-up, Operating, and. Service and Maintenance Instructions. The 58STA/STX 4-way Multipoise Gas Furnaces feature Carrier's.

. Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations. Book 1 4 PC 101 Catalog No. 535-80099 Printed in U.S.A. Form 58MXA-9SM Pg 1 11-02 Replaces: 58MXA-8SM Tab 6a 8a.

AIRFLOW EFFICIENCY RATING CERTIFIED UPFLOW CERTIFIED ® HORIZONTAL HORIZONTAL LEFT RIGHT DOWNFLOW AIRFLOW AIRFLOW REGISTERED QUALITY SYSTEM AIRFLOW SAFETY CONSIDERATIONS A93041 Recognize safety information. This is the safety-alert symbol Fig.

2—Multipoise Orientation When you see this symbol on the furnace and in instructions or ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS manuals, be alert to the potential for personal injury. WASHABLE FILTER IN FURNACE FILTER RETAINER WASHABLE FILTER FILTER SUPPORT FILTER RETAINER WASHABLE FILTER OR DISPOSABLE MEDIA WASHABLE FILTER OR FILTER IN FILTER CABINET DISPOSABLE MEDIA FILTER IN FILTER CABINET A00233 Fig. 4—Filter Installed for Side Inlet A00232 Fig. 3—Bottom Filter Arrangement To clean or replace filters, proceed as follows: If filter is installed in filter cabinet adjacent to furnace: Turn off the gas and electrical supplies to the unit before. Clean blower motor and wheel as follows: (1.) Connect 1 tube (blue or blue and white striped) from collector box. Turn off electrical supply to furnace.

Carrier Series 160

(2.) Connect 1 tube (violet or unmarked) from inducer 2. Remove main furnace door and blower access panel. Remove burner box pressure tube from gas valve regulator fitting. FIRE OR EXPLOSION HAZARD 7. Remove screws that secure manifold to burner box. Failure to follow the safety warnings exactly could result in serious injury, death, or property damage. Never test for gas leaks with an open flame.

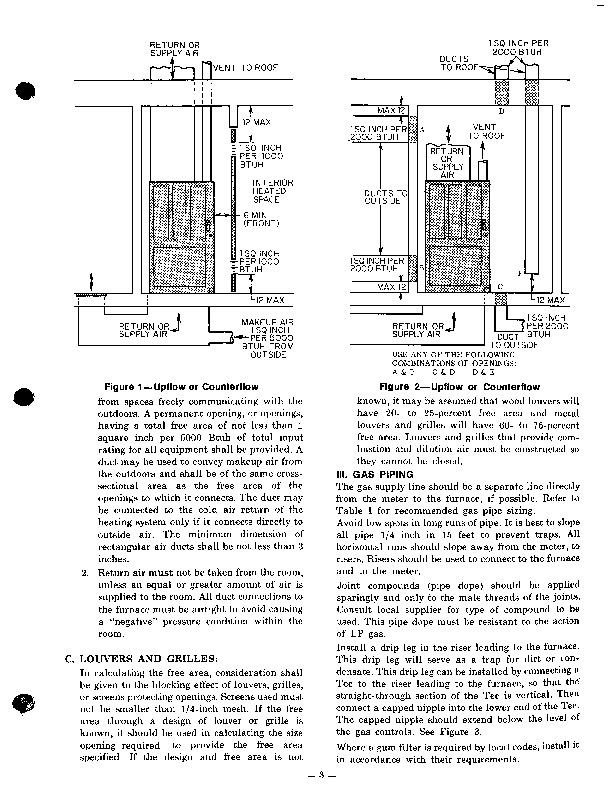

Check furnace operation through 2 complete heat operating PRIMARY HX INLET OPENINGS cycles. Look through sight glass in burner enclosure to check burners. Burner flames should be clear blue, almost transpar- ent. 9.) FIRE OR EXPLOSION HAZARD Failure to follow the safety warnings exactly could result in serious injury, death, or property damage. TUBE ROUTING Furnace is shipped from factory in upflow configuration. 2016 polaris 850 xp owners manual. Pressure tube and drain tube routing MUST match the diagrams below. Tube location when used in UPFLOW application Condensate Trap on LEFT Condensate Trap; Factory Installed Side Optional in Blower Shelf BURNER ENCLOSURE (Blower access panel removed) BURNER ENCLOSURE.

Turn off gas and electrical supplies to furnace. Remove main furnace door. Disconnect igniter wire connection. Check igniter resistance.

Using an ohm meter, check resistance across both igniter leads in connector. Cold reading should be between 45 ohms and 90 ohms. FIELD 24-V WIRING FIELD 115-, 208/230-, 460-V WIRING FACTORY 24-V WIRING FACTORY 115-V WIRING NOTE 2 THERMOSTAT FIVE WIRE FIELD-SUPPLIED TERMINALS DISCONNECT THREE-WIRE HEATING-ONLY 208/230- OR BLOWER DOOR SWITCH 460-V THREE PHASE 208/230-V SINGLE PHASE AUXILIARY 115-V FIELD- J-BOX SUPPLIED NOTE 1 DISCONNECT CONDENSING. 32 F MINIMUM INSTALLED AMBIENT OR FREEZE PROTECTION REQUIRED A93058 Fig. 13—Winterizing the Furnace Step 8—Checking Heat Tape Operation (If Applicable) If this furnace is to be operated in an unconditioned space where the ambient temperatures may be 32°F or lower, freeze protection measures must be taken. Reconnect drain cap to inducer housing. Record the code.

After the last code is displayed the control will perform the component test, and then return to normal standby 7. Replace main furnace door. Propylene glycol need not be removed before restarting furnace.

Carrier Furnace 58sta/stx Series 160 Manual

TO 115VAC FIELD DISCONNECT SCHEMATIC DIAGRAM (WHEN USED) BLOWER OFF DELAY LGPS NOTE #2 (NATURAL GAS & PROPANE) JUMPER SELECT EQUIPMENT GROUND DHUM CAP-1 MED LO NOTE #11 HEAT MED HI START SPARE-1 NOTE #10 HI/LO BLWR COOL EAC-2 Y/Y2 TEST/TWIN BLWM EAC-1. SERVICE If status code recall is needed, briefly remove then reconnect one main limit wire to display stored status code. On RED LED boards do not remove power or blower door before initiat- ing status code recall. After one status code recall is completed component test will occur.

LED CODE STATUS CONTINUOUS OFF - Check for 115VAC at L1 &. Copyright 2002 CARRIER Corp. Indianapolis, IN 46231 58mxa9sm Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations. Book 1 4 Tab 6a 8a PC 101 Catalog No.

Most Viewed Pages

- Beacon Lumber Practice Set Solution Manual

- Radical Platt Study Guide

- Flight Simulator Q400 Flight Manual

- Mercedes W124 200d Workshop Manual

- Chemistry And Art Laboratory Manual Answers

- Atlas Copco Xas 136 Service Manual

- Pmbok Guide 5th 2018

- Sea Doo 2015 Sportster Le Manual

- Peugeot 2007 Workshop Manual

- Mitsubishi Mm55sr Manual

- Citroen C2 Front Workshop Manual

- Engineer Characteristics Manual Usmc

- Roland 540v Service Manual

- Ccna 1 Companion Guide

- Omc Boat Motor Controls Manual

- 1992 Ford Escort Lx Manual

- Kawasaki Keyboard Manual

- Part Manual Honda 3000 Eu

- Camry 3vz Fe Service Manual Fulldownloads

- Quick Start Manual For Garmin Nuvi 2595lmt

- 2015 4l60e Rebuild Manual