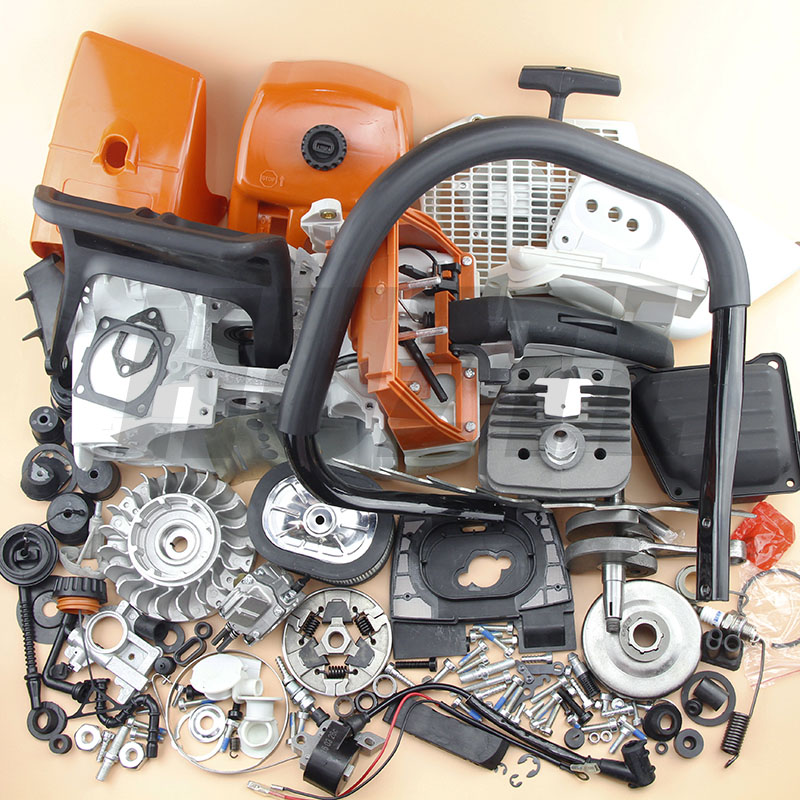

Stihl Ms 230 Chainsaw Repair Manual

The operating and maintenance instructions in chapter 'Safety. Precautions and Working Techniques' before using your chain saw. For further information you.

. STIH) STIHL MS 210, 230, 250 2003-04. 8.5.1 Elastostart 8.5.2 Tensioning Rewind Spring Pawl AV Handle System/ Handle Housing Annular Buffers Front Handle Handle Housing Switch Shaft Contact Spring Throttle Trigger/ Interlock Lever © ANDREAS STIHL AG & Co. KG, 2007 MS 210, MS 230, MS 250.

Use the part numbers to identify the tools in the 'STIHL As the design concept of model Special Tools' manual. MS 210, 230 and 250 chainsaws is The manual lists all special almost identical, the descriptions servicing tools currently available and servicing procedures in thus from STIHL. Do not smoke or bring any fire, flame or other source of heat near the fuel. All work with fuel must be performed outdoors only. Spilled fuel must be wiped away immediately. MS 210, MS 230, MS 250.

Toyota starlet 1999 model am pictures. (with bar and chain): 12,500 rpm 14,000 rpm 14,000 rpm Idle speed: 2,800 rpm Clutch: Centrifugal clutch without linings Clutch engages at: 4,100 rpm Crankcase leakage test at gauge pressure: 7.25 psi under vacuum: 7.25 psi MS 210, MS 230, MS 250. Bosch WSR 6F NGK BPMR 7A Electrode gap: 0.5 mm (0.02 in) Chain Lubrication Fully automatic speed-controlled oil pump with rotary piston Oil delivery rate: approx.

7.5 cc/min (0.46 cu in/min) at 10,000 rpm MS 210, MS 230, MS 250. DG 8x18 Guide bar mounting M12x1 Carrier (clutch) M14x1.25 Spark plug Collar locknut Muffler Collar locknut Filter housing/carburetor 0.27 Collar nut M8x1 Flywheel to crankshaft M12x1.5 Decompression valve Spline screw IS-DG5x16 Spiked bumper 0.37 MS 210, MS 230, MS 250.

This procedure ensures that the screw engages properly in the existing thread and does not form a new thread, which would weaken the assembly. Note: Power screwdriver speed setting for polymer: – DG screws max. 500 rpm MS 210, MS 230, MS 250. Fit chain of correct pitch Saw chain does not stop Brake spring stretched or broken Fit new brake spring immediately when brake is activated Brake band stretched / worn / Fit new brake band broken MS 210, MS 230, MS 250. Lubricating oil on rewind spring Apply a few drops of kerosine becomes viscous at very low (paraffin) to spring, then pull rope outside temperatures (spring carefully several times until normal windings stick together) action is restored MS 210, MS 230, MS 250. Install new oil pump Machine losing chain oil Oil seal leaking Replace oil seal Bore in pump housing worn Install new oil pump Oil pump delivers too little oil Oil pump worn Install new oil pump MS 210, MS 230, MS 250.

Set air gap correctly coil and flywheel Flywheel cracked or has other Install new flywheel damage Crankcase damaged (cracks) Install new crankcase No ignition spark Check operation of Master Control lever, ignition module and ignition lead MS 210, MS 230, MS 250. Inlet needle sticking to valve seat Remove inlet needle, clean and refit Connecting bore to atmosphere Clean bore blocked Diaphragm gasket leaking Fit a new diaphragm gasket Metering diaphragm damaged or Fit a new metering diaphragm shrunk MS 210, MS 230, MS 250. Fit a new pump diaphragm fatigued Main jet bores or ports blocked Clean the bores and ports Fuel pickup body dirty Clean the pickup body, fit a new filter Fuel strainers dirty Clean the fuel strainers MS 210, MS 230, MS 250. Decompression valve sticking Replace the decompression valve Engine overheating Insufficient cylinder cooling. Air Thoroughly clean all cooling air inlets in fan housing blocked or openings and the cylinder fins cooling fins on cylinder very dirty MS 210, MS 230, MS 250.

If the clutch drum has to be replaced, also check the brake band – b 5.4. – Remove the rim sprocket, if fitted.: Pull off the clutch drum / chain sprocket. MS 210, MS 230, MS 250.: Pry the plug (2) out of the front right-hand AV element. – Unscrew the spark plug. – Close the decompression valve, if fitted.: Push the locking strip (1) 0000 893 5903 into the cylinder. MS 210, MS 230, MS 250.

– Pull the clutch shoes off the carrier. Assembling the clutch:: Clamp the clutch in a vise.: Slip the retainers onto the clutch shoes. MS 210, MS 230, MS 250. Deceleration of the saw chain is imperceptible to the eye.: Fit the shutter so that its lugs engage the recesses in the handle housing. – Install the air filter – b 11.1. MS 210, MS 230, MS 250.: Remove strap from bell crank off the anchor pin and take it off pivot pin (1).

The bell crank.: Push the strap sideways and lift it off the hand guard pivot pin (2). MS 210, MS 230, MS 250. (2) off their pivot the hand guard so that the short pins and lift away together.

Arm of the bell crank points to top of hand guard. – Pull the bell crank out of the hand guard.

MS 210, MS 230, MS 250. 'snatching' during the first few brake applications.: Check that flat spring (1) is: Attach the brake spring to the bell properly located on face (2) of crank.

Hand guard bearing boss. MS 210, MS 230, MS 250. (1.5 lbf.ft). – Fit upper bumper strip on tensioner.

– Install clutch drum/chain sprocket – b 5.1. – Check operation of chain brake – b 5.4.1.: Pull the spur gear out of the cover. MS 210, MS 230, MS 250.: Pull off or lever off the cover plate: Remove the gasket (1) and heat – depending on type fitted. Shield (2), if fitted. – Remove spark arresting screen, if fitted. Clean the screen or fit a new one if necessary. MS 210, MS 230, MS 250.

– Remove the carburetor – b 11.2.2. – Set the piston to top dead center (T.D.C.). This can be checked through the inlet port.: Inspect carburetor gasket and fit a new one if necessary. MS 210, MS 230, MS 250. – Remove the flange. Pump 0000 850 3501. 20 seconds, the engine or decompression valve, if fitted, is – Remove the sealing plate.

– Install the muffler – b 6.1. MS 210, MS 230, MS 250. 0000 850 3501 to test crankshaft. Flange nipple.: Close the vent screw (1) on the pump.: Operate the lever (2) until pressure gauge (3) indicates a vacuum of 0.5 bar (7.25 psi). MS 210, MS 230, MS 250. Ignition side: – Remove the flywheel – b 7.5.: Apply puller (1) 5910 890 4400 (jaws 0000 893 3711 with No. – Clamp the puller arms.

– Pull out the oil seal. MS 210, MS 230, MS 250.: Place the oil seal (1) in position: Take out the ground wire with the clamping ring facing up.

Stihl Ms 230 Chainsaw For Sale

Fastening screw.: Screw the guide sleeve (2) 1123 894 7700 onto the crankshaft. MS 210, MS 230, MS 250. – Apply a thin coating of sealant to the outer diameters of the oil seals – b 13.: Pull the engine pan off the – Lubricate piston and piston ring cylinder. MS 210, MS 230, MS 250.: Push the manifold on to the the engine pan mating face – intake port so that the straight b 13.

Faces are in alignment. Follow manufacturer’s instructions Assemble all other parts in the for use of sealant. Reverse sequence. MS 210, MS 230, MS 250.

5910 890 2210 as shown: the connecting rod. A = 16 mm (11/16') Installed position of piston: b = 8 mm (5/16') 1 = Arrow 2 = Long stub of crankshaft MS 210, MS 230, MS 250. Position the sleeve so steady, center the tool shank that the inner pin (1) points exactly and press home until the toward the flat face (2) of tool's snap ring slips into the groove. MS 210, MS 230, MS 250.: Install the new piston rings in the – Remove the piston – b 6.6.

Grooves so that the radii face upward.: Remove the retaining ring (arrow). – Install the piston – b 6.6.

MS 210, MS 230, MS 250. – Install the piston – b 6.6. – Install new decompression valve and torque down to 14 Nm (10.5 lbf.ft). – Refit the front handle. The electronic (breakerless) ignition system basically consists of an ignition module (1) and flywheel (2).

MS 210, MS 230, MS 250. – Install the air filter – b 11.1. – Fit spark plug boot over the ignition lead. – Use pliers to grip the end of the ignition lead inside the spark plug boot and pull it out.

MS 210, MS 230, MS 250. If no spark is visible, check the – Set Master Control lever to '1'. Wiring harness and contact spring – b 7.4. The measured resistance must be infinitely high.

If not, install a new Master Control lever. MS 210, MS 230, MS 250.: Pull the short circuit wire off the tag on the ignition module.: Take out the screws (arrows). – Pull the ignition module forward a little.: Take the short circuit wire (1) out of the retainer (2). MS 210, MS 230, MS 250. Reassemble all other parts in the reverse sequence. If the flywheel cannot be removed by hand, screw on the puller (1) 1116 893 0800 and tap its end to release the flywheel. Remove the puller.

MS 210, MS 230, MS 250. Leg spring hook in center of ignition lead?

Boot damaged? If necessary, install new spark plug boot and/or leg spring Test ignition system with ZAT 3 or ZAT 4 (use ZAT 3 as main spark gap – see TI 32.94) MS 210, MS 230, MS 250.

– Spark plug boot: Holes/cracks? – Resistance spark plug boot to ground: spec. 1.5 – 12kΩ – Check resistance of ignition lead: spec.

Most Viewed Pages

- Sturdee Bench Grinder Manual

- Aphex 105 Logic Assisted Gate Manual

- Zongshen 250 Owners Manual

- 2017 Chevrolet Trailblazer Factory Service Manual

- Craftsman 82017 Manual

- Alcatel One Touch 4030 Manual

- Pfaff Sewing Machine Instruction Manual 238 6x6

- Mori Seiki Service Manual Mt2017

- Gmc Envoy Sle Owner Manual

- Guide For Tamilnadu School

- 2018 Honda Crf50 Manual

- 2017 Chrysler Pacifica Wiring Diagrams Manual

- 2018 Vw Beetle Turbo Owners Manual

- Prentice Hall Biology Ch 37 Guide

- 2016 Crown Victoria Repair Manual

- Yokogawa Training Manuals

- 2015 Oldsmobile Alero Haynes Manual

- Echo Manual X752018021

- Lincoln Sa 200 Gas Welder Repair Manual

- P1225 Service Manual

- Flight Manual Pa 18

- 92 96 Camry Manual